IRON REMOVAL

Specifically designed for the very high concentrations of iron in our water

What is IRON REMOVAL?

Clean & Green Iron Removal Water Filters are the ultimate solution in iron removal. Specifically designed to cope with the very high concentrations of iron in our water, especially here in WA, our filters are the most economical, effective, and environmentally friendly ground water treatment systems on the market.

Our unique systems are manufactured based on their hydro-automatic system known as ‘Deferum’ which is designed for the non-reagent removal of:

- Dissolved iron

- Dissolved gases (Hydrogen Sulphide, Carbon Dioxide, Methane, Radon, etc.)

- Suspended and colloidal particles

Iron Removal Filters can process water 24 hours a day, 365 days a year, hydro-automatically with no need for:

- Chemical treatment of the water

- Replacement or washing of filters

- Continually scalping, cleaning and replenishing sand filters

Iron Removal Filters can also be used as a pre-treatment stage before:

- Reverse Osmosis

- Ion-Exchange

- Micro-filtration

- And many more…

Clean & Green Iron Removal Filter Advantages

- Eliminates iron staining

- Chemical free

- Improves water quality for agriculture and livestock

- Reduces irrigation and pipe blockages creating less maintenance

- Low maintenance and user friendly

- No need for regular checking

- Range of sizes to suit requirements

Specifications

| SPECIFICATION | DF12 | DF24 | DF48 | SF100 | SF200 |

|---|---|---|---|---|---|

| Filtered Water | 12,000 litres water p/day | 24,000 litres water p/day | 48,000 litres water p/day | 100,000 litres water p/day | 200,000 litres water p/day |

| Height of Main Tank | 1.5m | 2.2m | 2.2m | 2.5m | 2.5m |

| Diameter of Main Tank | 0.75m | 1.0m | 1.0m | 1.65m | 1.65m |

| Top Height of Piping | 2.8m | 3.5m | 3.5m | 5.0m | 5.0m |

| Feed Water Pressure | Supplied from bore at 5bar | ||||

| Water Consumption for Backwash | Up to max 1.5% of daily output | ||||

| Duration of Backwash | Approx. 3 minutes + siphon drain | ||||

| Automated Control Board | Manual backwash switch / Automated backwash function / Ability to control two pumps / 24V High level storage tank control / Compatible via signal for 3phase pumps / 24V Actuator Control linked to timer | ||||

| MORE*** | Need more water? Larger quantities of water can be provided by way of multiple modules of the SF200 | ||||

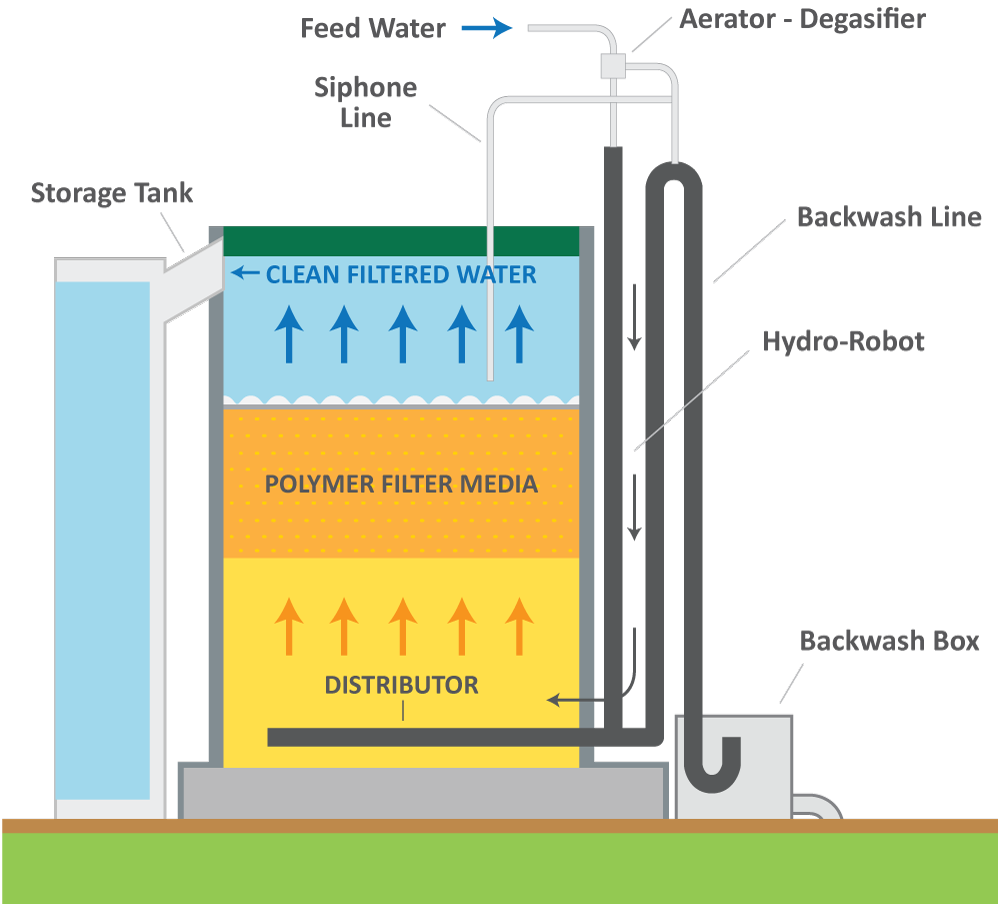

Filtration Process

1

Feed Water is pumped from the bore and supplied at 5bar to the Aerator-Degasifier where gases are removed, and oxygen is dissolved into the water.

2

Feed Water then flows down the Hydro-Robot, through the Distributor and into the filter tank where iron and particles are collected by Polymer Filter Media

3

Clean Filtered Water then flows via gravity into storage tanks

4

Automated Control Board triggers backwashing by Clean Filtered Water flowing back down through media bed washing out collected iron/particles and exiting via Backwash Line

5

Backwash automatically stops when clean water level drops below vacuum Siphon Line